Why tank (waterproof) your bathroom?

An adhesive or grout that claims to be ‘waterproof’ is often just water resistant, meaning it isn’t affected by water. Water can pass through the product without causing any damage to the surface and therefore, a product can sit on a shelf with a waterproof label as happy as Larry even if, technically, it doesn’t waterproof. If we look at the definitions* the difference becomes clear:

Waterproof: unable to be penetrated by water.

Water-resistant: partially able to resist the penetration of water

We know that people (think families with 2.4 children) spend a large amount of time in the shower and, whilst the grout and adhesive may remain unharmed, the background to which the tiles are placed can become continually exposed to water if it isn’t fully waterproofed. This can cause a large amount of damage behind the surface.

With the increasing popularity of wet rooms and power showers, pounding water will generally hit the same tiles many times a day. Grout is porous and will allow moisture through it and, whilst the properties of the grout are unaffected, over a period of time moisture and water are absorbed by the porous background and will lead to failures. Tanking will give builders the confidence that, should the installation develop problems behind the tile face, these problems will not be transferred to the substrate. It is a way for them to protect the fabric of the building they’re working on, prolonging the life of bathrooms, wet rooms and kitchens up and down the country.

We can also offer a water PROOF grout. Other than the obvious benefit of being waterproof, this grout because of its waterproofing qualities, is also extremely resitant to discolouring and staining. Therefore reducing the likelyhood of mould build-up and the regular bleaching that is required to curtail it. Click here for water proof grout.

What are the pros for your customer?

Not tanking can be a huge false economy. Leaking water can necessitate joist replacements, ceiling replacements and other costly and highly inconvenient building repair work. With tanking, total piece of mind is guaranteed – it not only prevents water saturating the floor and reduces the risk of unsightly black mould forming but it also prevents more serious issues such as de-bonding of tiles and even complete floor collapse.

Tanking can be a huge selling point for homeowners when packing up and moving on, and can reduce unnecessary costs to a property. By tanking a new bathroom, a homeowner can be confident that their money has been well spent - and what homeowner wouldn’t like to hear that news? It has also been heard that tanking could lower insurance premiums…It’s amazing what a little waterproofing can do…

When to recommend tanking

Stocking tanking kits alongside adhesives specific to bathrooms, wet rooms and kitchens provides an excellent opportunity to recommend an additional product to your customer and make an extra sale. Some builders still think that grouting makes surfaces waterproof and this is certainly not the case – through some gentle tips and advice on the benefits of tanking you can help your customer portray a sound product knowledge as well as keep your tills ringing.

Tanking is now becoming a big industry in itself. Whilst there are other products available, such as waterproof tile backer boards, these can’t compete with the results you get from tanking. Cement boards are only water resistant and will still absorb water (which can affect the substrate underneath) and, in showers, there is never a perfect fit from the board to the shower tray. Tanking is a full system in itself and can fill all these voids.

Homeowners are becoming more savvy to the fact that there is more to installing a new bathroom than choosing tiles, sticking and spreading. This is even more so in a time when people are opting to do up their homes rather than sell them. With the Internet at our fingertips, researching jobs before even speaking to a builder is commonplace to make sure they know exactly where their money’s being spent, and to avoid the dreaded wrath of the cowboy builder.

With this nifty product knowledge, you can stay ahead of the game and act as a fountain of information for your customers to keep them coming back and to keep your figures looking healthy.

If you require more information on tanking your wet room or bathroom, why not call us and speak to one of our technical assistants on 01626 324234

What surfaces can you tank?

Tanking is suitable for use on a wide variety of surfaces including:

- Concrete

- Cement: sand rendering

- Plaster

- Plasterboard

- Moisture stable timber boards

- Lightweight tile backing boards

- Fibre cement boards

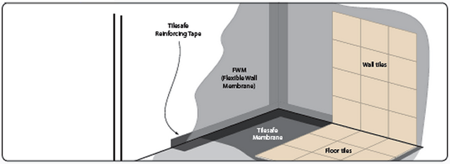

Below is a diagram giving examples of the principles of water proofing solutions for both timber and concrete floors.

Various paint on tanking kits are available to prime, seal and protect. The primer should be applied to clean and dry walls and left until touch dry. To seal, the waterproofing coating should then be applied to all corners and any other cracks and joints before the tape or sealant is used (this will vary depending on the kit). Then, to protect, a second layer of waterproof coating should be applied to fully protect all areas. In general, the background should be ready to receive tiles after 24 hours.

Sheet membrane waterproofing kits are also available and although initially may appear slightly more expensive, in real terms they normally work out at an economic advantage for at least a couple of reasons. Firstly, is because some membrane kits incorporate a de-laminating layer that allows for the differing sub straights to expand and contract under varying temperature differentials within the wet room. It is important to keep in mind that because bathrooms and wet rooms are normally the warmest and dampest room within a property, which are exactly the conditions to create the greatest expansions within the building sub straights, so having a de-laminating layer incorporated within a water-proof membrane is a very sensible solution. Secondly, sheet membrane kits are far quicker to install and require no drying time like the paint on equivalents, therefore saving a considerable amount of labour time and the cost that that would incur.